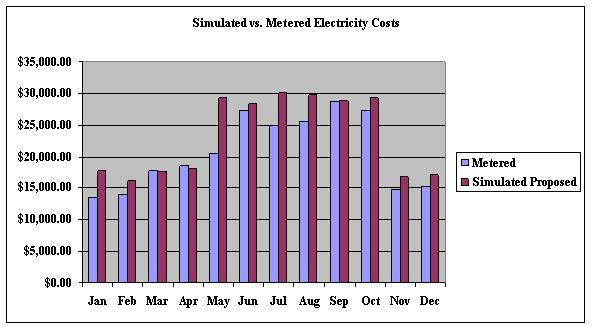

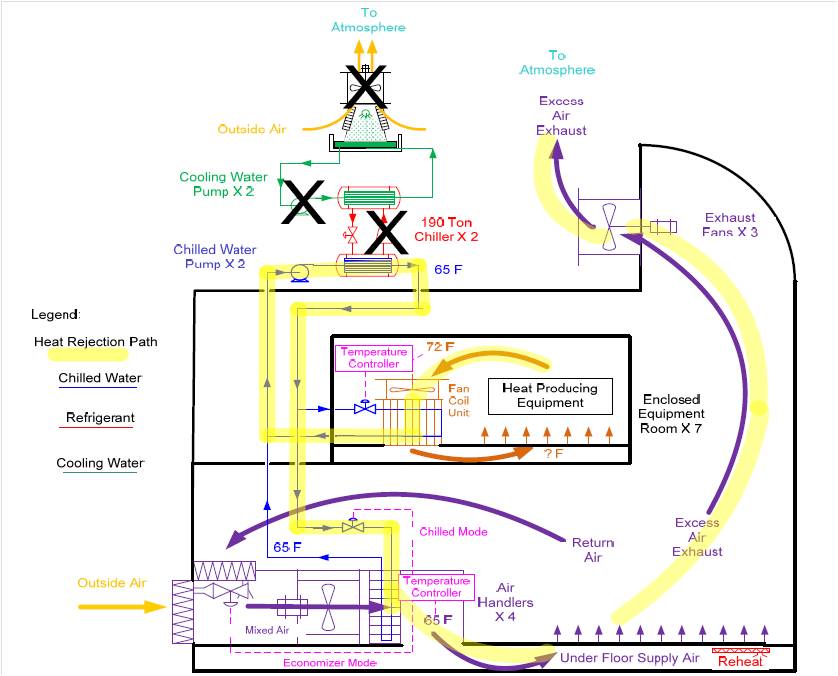

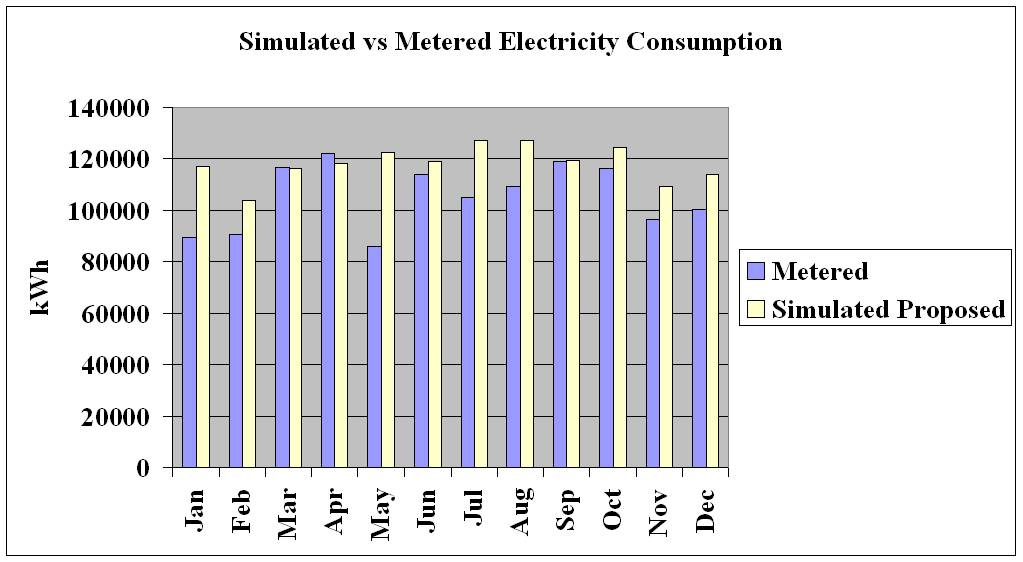

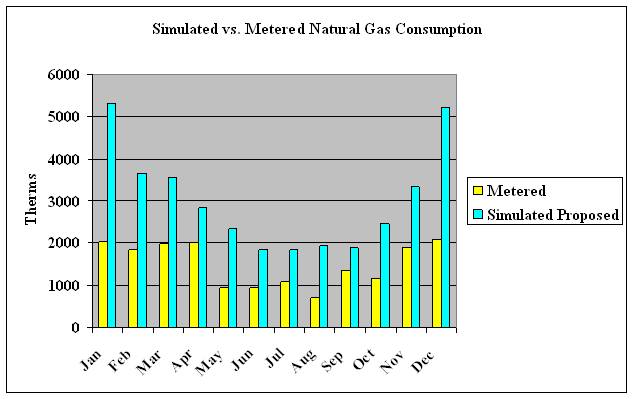

The initial energy analysis influenced design of the building envelope and glazing systems for optimum energy efficiency. The mechanical systems feature an energy efficient central plant providing the building with its own chilled water utilizing high-efficiency VFD chillers which operate at 0.29 kW/Ton. The cooling towers have a 5° F approach with 10 HP premium efficiency motors and VFD’s. Based on the energy model of the building (created in EnergyPro version 4.4), the design exceeds California’s Title 24-2005 energy code by 23.1% and by the end of design and construction, a building had been created that could utilize architectural features, energy efficient HVAC equipment, controls, and efficient lighting to reduce energy consumption by a predicted 16.1% below ASHRAE 90.1-2004. A review of actual metered energy use versus the predicted energy use will show that the building is performing nearly 28% better than expected, at about 45 kBtu/sf/yr in 2010 (Figures 1 & 2). The design team was able to reduce the overall building height by 11 feet (from 66’-6” to 55’-6”) by relocating the mechanical system beneath raised floors, saving space and cost on ceilings, ducting and controls. The under floor air distribution (UFAD) system is used to deliver air to the occupied zones of the building and is supplied by four large air handlers supplying up to 55,000 CFM. On the design day, the supply air temperature from the UFAD system is 65° F and is maintained either by mixing outside air with return air in an economizer mode when the ambient temperature is below 65° F, or by cooling the air supply with chilled water when the ambient temperature is above 65° F.

Temperature control for thermal comfort is achieved through VAV controls and hot water reheat in the zones. Excess air admitted from outside, either for economizer cooling or to maintain minimum ventilation rates, is exhausted from the building via the atrium and three rooftop exhaust fans that modulate to maintain constant building pressure. A chiller plant on the library roof supplies chilled water for the entire building, and is comprised of two 190 Ton centrifugal chillers, associated cooling water pumps, chilled water pumps and cooling towers.

Contrasting with overhead mechanical systems, the library’s under floor approach also allows for controlled thermal stratification, higher supply air temperatures, and reduced static pressures in the under-floor plenum, all resulting in an overall reduction in energy consumption. Due to the 65° F supply air temperature for the UFAD system, the reheat load is much lower than that of an overhead system, which would require heating the supply air in the winter from 55° F instead of 65° F. Further, the mild Monterey Bay climate helps to maximize the outside air economizer’s efficiency, due to the combination of relatively low outdoor ambient dry bulb temperatures and the elevated supply air temperatures.

The library’s architectural features complement the mechanical and plumbing designs to further promote energy efficiency and cost savings. The building’s North-facing orientation allows for the interior reading areas and study spaces to receive plenty of ambient daylight through high performance thermal glazing with low-e coating with 70% visible light transmittance and a 0.44 shading coefficient, resulting in an excellent light-to-solar gain ratio of 1.84 and overall U-value of 0.29 in winter nighttime conditions. The building’s 3-story axial atrium with fully-glazed ends has an arched roof which creates a light scoop, bringing optimal daylight beyond the perimeter zones and into the building’s interior. The sloped roof and high north-facing windows are classic methods of daylight harvesting, allowing for primarily diffuse daylight to penetrate more deeply into the space than would have been possible with a flat roof and lower window head height. An exterior louver system further eliminates solar glare from the book stacks and occupied zones, and relieves the East and West façades of increased solar heat gain, while still allowing for expansive views to the exterior for students.

Besides the system’s design resulting in multiple energy efficiency benefits that are inherent to UFAD design, it also provides multiple advantages in regards to indoor air quality and thermal comfort. Increased occupant control at the floor level (every work station has its own individual ventilation control) leads to improved air quality as well as better thermal comfort, which results from air being delivered nearer to the occupant and more efficiently removing contaminants from the occupied zone. The outdoor air economizer allows the return air temperature to be higher (80° F as opposed to the 75° F baseline design), which results in the building being supplied with 100% outside air for more hours throughout the year. The building’s 3-story atrium was taken advantage of as a relief air path. The provision of operable windows for smoke control also affords the opportunity to naturally ventilate the building in the event of a power outage.

Thermal comfort and ASHRAE Standard 55 – 2004 were considered in the design and selection of the mechanical system. Activity and clothing levels were assumed to be consistent with a library and office setting in a temperate climate, and were “seated, quiet” (1.0 met), and “ASHRAE Standard 55 – Summer/Winter” (0.60/0.80 clo), respectively. Air velocity was assumed to be 20 fpm, relative humidity 50%, and the design room temperatures for cooling set at 75°F/63°F WB. These values, according to ASHRAE Standard 55, result in ideal comfort conditions, and based on a lack of occupant complaints, the system appears to be functioning well.

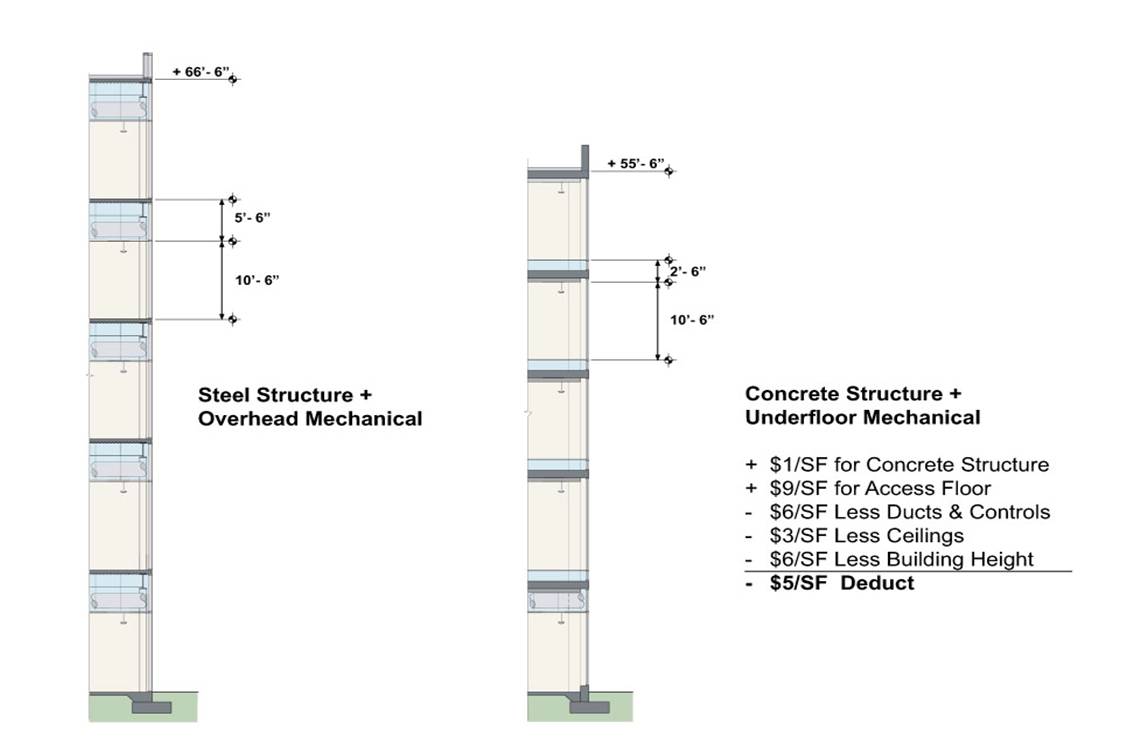

The Under Floor Air Distribution system was used in conjunction with a concrete structure to reduce ceiling and floor-to-floor heights. A cost analysis was done to compare the original steel structure with overhead mechanical system to a concrete structure with UFAD scenario, ultimately achieving a $5 savings per square foot savings (Figure 3). Stack supports were carefully designed to work with the raised floor and provide flexibility in infrastructure and information delivery in an extremely energy- and cost-efficient manner. The UFAD system, coupled with an extremely efficient magnetic-bearing, frictionless centrifugal chiller resulted in an innovative mechanical system which is providing the owner with high cost savings and the occupants with a comfortable space to work and study in.

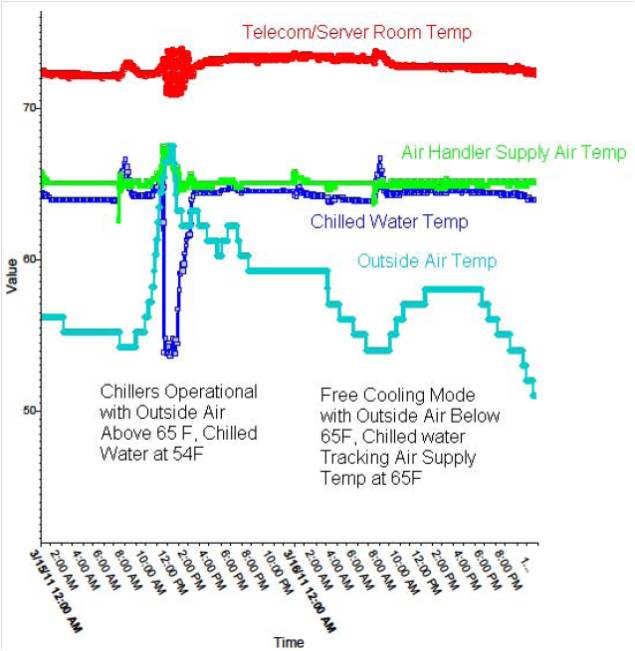

Building operations were evaluated in 2010 and resulted in an energy retrofit and study called “Free Cooling Mode” by CSU Monterey Bay, leading to significant energy savings. Soon after building start up in 2009, it was noted that any time the outside air temperature was less than 65 F, the four air handlers supplying the under floor system placed no demand on the chiller plant, leaving the chiller plant with only the demand of the equipment room fan coil units. The equipment loads for these fan-coil units are significantly less than was anticipated by the users and design team; only 5 tons, instead of the expected 27 tons, or 18% of the design load. Low load operation had been foreseen in the building design and the chiller plant had been specified to be able to operate at very low loads with hot gas bypass, but operating this low was not ideal. Due to the mild coastal climate of Monterey, there are only approximately 1,222 hours per year when the outside air temperature is above 65° F. The retrofit project resulted in a solution that took advantage of the economizer mode of the building air handlers, greatly reducing hours of operation for the building chiller plant. The modification reduced chiller plant hours of operation from 8,760 hours per year to an estimated 1,222 hours per year, thus saving 243,647 Kwh/year of electricity. Project implementation was simple and only required changes to the computerized building management system (BMS) sequences.

Implementation of the free cooling system only required changes to the computerized building management system (BMS) sequences. A further analysis of the library’s utility bills shows that the building is performing in line with or better than predicted, saving 16.3% of the total proposed cost, or $52,528 per year.